The correct and reasonable use of the edging machine can not only ensure the normal production, but also prolong the life of the machine. Here is an introduction to the matters needing attention in the correct use of the edging machine.

1. For all newly purchased edging machines, be sure to read the instruction manual before using it. After understanding the transmission principle of the machine, the functions of various handles, handwheels, electrical buttons, waterway and airway regulating valves, and mastering the knowledge of machine maintenance, you can operate the machine.

2. The quality of the grinding head of the edging machine has a great influence on the grinding quality of the glass. The position of the grinding head and the moving gap have been adjusted before leaving the factory. Generally, do not move the rest except the forward and backward grinding heads during use. , So as not to affect the grinding quality. In addition, the back position of the grinding head is not easy to be too large, otherwise the waterproof cover will be easily damaged, causing water leakage, and the motor is likely to burn out.

3. Adequate cooling also has a greater impact on the grinding effect. Always check the cooling pipeline for blockage. Especially the pipeline of the linear edging machine is easy to be blocked by the bristles, and it is not easy to be noticed after blocking, which will cause insufficient cooling and affect the quality of edging.

4. The CVT used by the edging machine must be in the open state when adjusting the speed, otherwise the CVT of the edging machine will be easily damaged.

5. Precautions when using the special-shaped machine: ① Whether the height of the suction cup of the special-shaped machine worktable is consistent has a greater impact on the grinding effect. When assembling, the manufacturer has carried out self-grinding on the five sets of suction cup holders, and selected the suction cup glue with the same thickness to keep the height of each suction cup consistent. Therefore, do not disassemble the suction cup under normal circumstances. If the suction cup glue is damaged, you must choose the same thickness to replace it. ②After the vacuum pump of the special-shaped machine is used for a period of time, the vacuum degree will drop (that is, the suction power will drop) due to water intake and other reasons. Therefore, pay attention to check and eliminate the fault. Otherwise, the machine will work under the condition of insufficient suction, which will affect the grinding quality, on the other hand, it is also prone to safety accidents.

6. Precautions when using the linear edging machine: The working method of the linear edging machine (straight edge machine, round edge machine, beveling machine) is to clamp the glass through the front and rear pressure plates and drive its linear motion for grinding. Two points must be paid attention to during use: ①The joint surface of the front and rear pressure plate and the guide rail should be frequently lubricated, otherwise the normal service life of the machine will be affected due to the premature wear of the front and rear pressure plate and the working surface of the guide rail. Although some models have automatic lubrication devices, you should always check whether the lubrication pipeline is unblocked; ②The clamping force should be appropriate when clamping the glass, too loose will affect the grinding quality, and too tight will increase the load of the machine, which is easy to produce the phenomenon of shaking and crawling, it is easy to pinch the glass when the glass is thinned. The clamping force can be tested with a slightly larger glass clamp on the machine, that is: clamp the glass in the middle of the machine, move the glass with both hands in the stopped state, and feel that the clamping force is adjusted to the degree when the hands can't move it.

7. Precautions when using the profiling machine: ①The profiling of the profiling machine has a great influence on the grinding accuracy. The working surface that depends on the template must be made of accurate shape and size, and the finish must be high. If it is shaped by template, the transition must be smooth. ②When replacing the template and the suction cup, be sure to keep the working surface of the suction cup level, otherwise the grinding quality will be affected.

8. Precautions when using the double-side edging machine: ① The double-side edging machine is a higher-grade edging machine. It is best to appoint two or three people to operate it to ensure correct operation. ②When there is an error or failure in the procedure of the double-side grinding, it is best to ask the original manufacturer to send someone to repair and debug. Under normal circumstances, do not disassemble and repair, so as not to mess up the procedure and cause the production to stop.

2025-11-07

2025-11-07

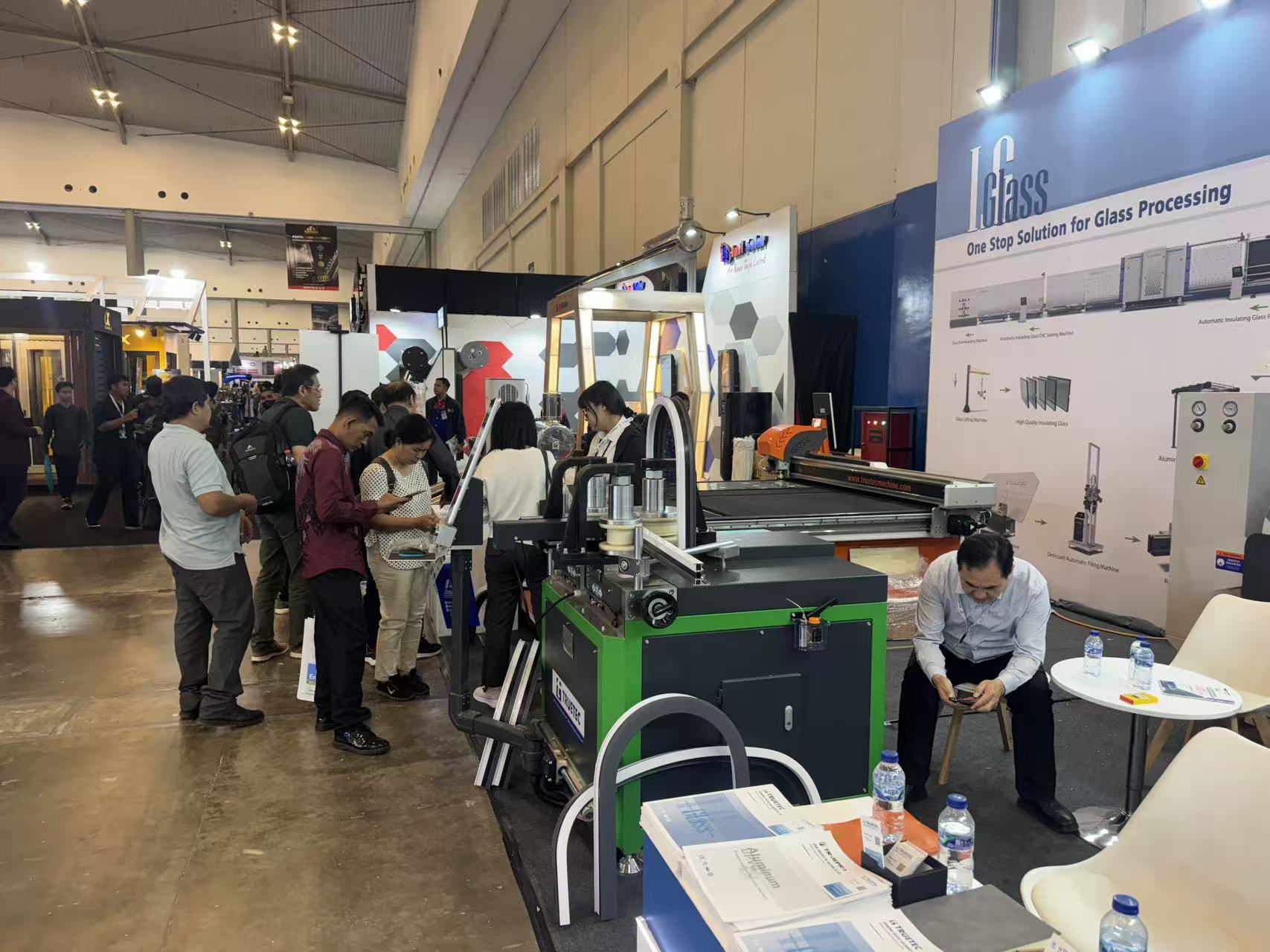

We are pleased to announce our participation in the upcoming INDO BUILD TECH 2025,···

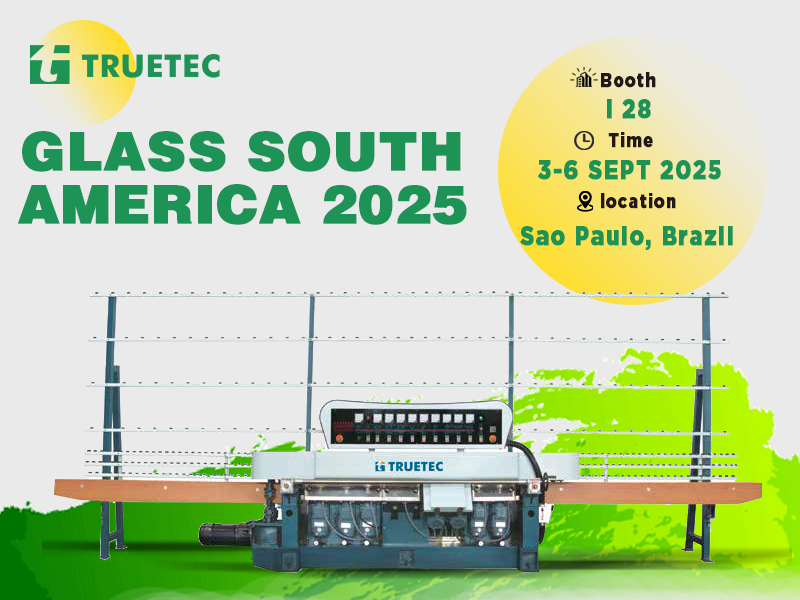

2025-08-02

2025-08-02

Join Us at GLASS SOUTH AMERICA 2025!We’re thrilled to invite you to visit us at Bo···

2024-12-17

2024-12-17

TRUETEC recently participated in GlassBuild America, the largest event for the gla···

Every machines can be customized to meet your special requirements.

Get A Quote

Shandong Truetec Company is a manufacturer of glass processing machines, such as insulating glass.